Photo by Liz Silvia

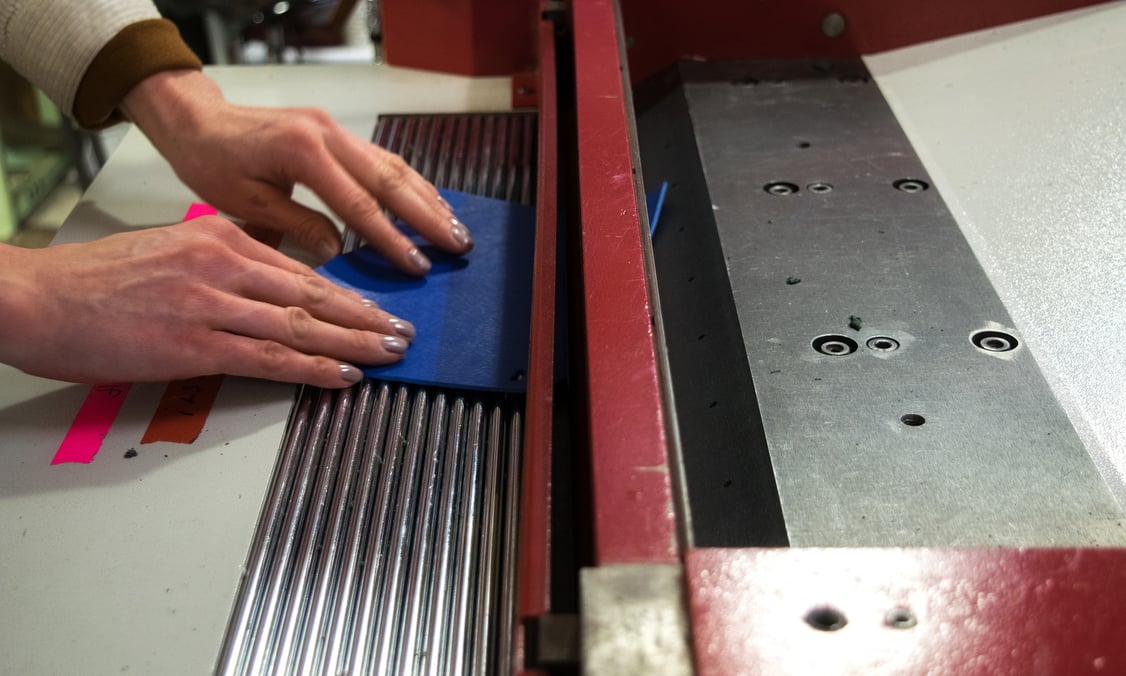

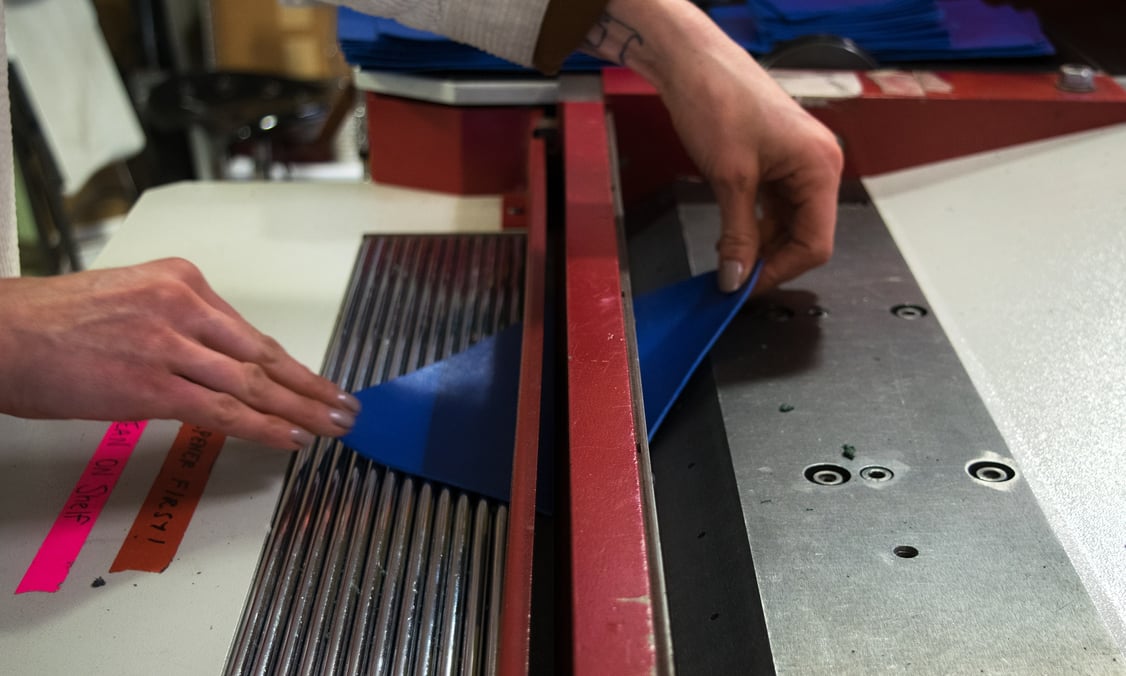

In the studio today we’re following the journey of our electric blue Tripp handbag from the cutting table to the splitter. By shearing the 37 pieces lengthwise down to a specific thickness, the weight of each is made even, allowing the finished bag to retain its structure and stand on its own.

Photo by Liz Silvia

This is particularly essential for the Tripp. Compared to one of our more malleable tote bags, variations by even one-tenth of an inch from one piece to another can mean the difference between a perfectly balanced bag that remains upright and one that tends to fall to one side or feel less uniform in places. Taking care to preemptively measure every piece’s thickness avoids these potential issues, and helps to create a light but strong sturdiness that does wonders for the bag’s aesthetics and resilience.

Photo by Liz Silvia

A great deal of consistency is required when doing this, and the process is time-consuming, but splitting our leather allows us to be true to our quality-based values and to feel good about the integrity of each bag that leaves the studio. Check back next Monday to see where our darling Tripp is in its journey to completion and to your doorstep.

Leave a Comment